Home » Accessories

Eliminates manual material handling by automatically conveying raw material to the hopper or dryer. Compact, efficient, and programmable.

Used to maintain mould temperature, especially for high-performance polymers. Improves

part finish, reduces warpage, and enhances cycle consistency.

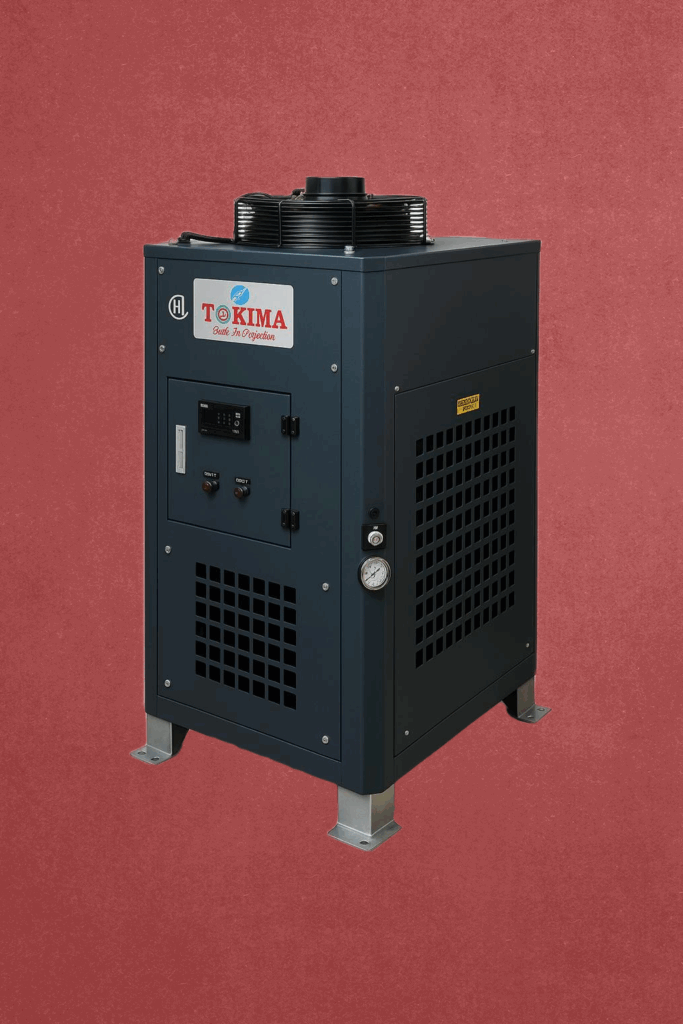

TOKIMA Water Chillers are engineered to deliver consistent cooling performance for plastic injection molding operations. By maintaining stable mold temperatures, these chillers help improve product quality, reduce cycle times, and enhance overall efficiency in production. Now available in capacities from 2TR to 20TR, our range includes compact units for small-scale operations as well as high-capacity models for large industrial setups.

Built for continuous operation, this grinder handles a wide range of materials including ABS, HDPE, LDPE, PC, PVC, and PET. Its heavy-duty blades and energy-efficient motor ensuring long-lasting performance.

Our TOKIMA Hopper Dryer ensures optimal material pre-processing by eliminating moisture from plastic resins before moulding. Available in 25 kg to 200 kg capacity, it features precise temperature control, fast drying cycles, and energy efficiency—making it ideal for a wide range of polymers like ABS, PC, Nylon, and more.

Fast & Reliable Resin Drying

Removes moisture content from raw plastic pellets to prevent product defects. Digital control and uniform airflow guarantee efficient drying.

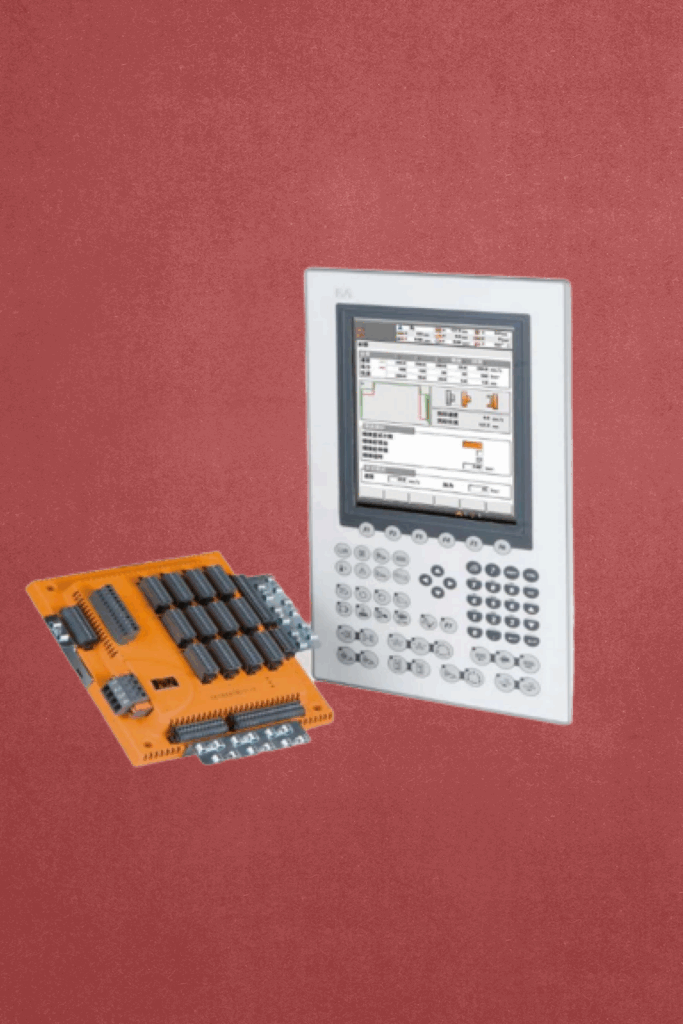

A world-class Austrian controller that ensures precision, consistency, and flexibility in operation. The 10.4″ TFT colour LCD provides clear visualization, while multi-language support makes it user-friendly across regions.

Consistent Masterbatch & Resin Mixing

Efficiently blends plastic granules with masterbatch to achieve even colour distribution. Available in both vertical and horizontal configurations.

Designed for quick mould changes and secure holding, these clamps ensure accurate alignment and reduce down time.

High-performance screw-barrel assemblies that ensure optimal melt quality, high injection speed, and reduced material degradation.

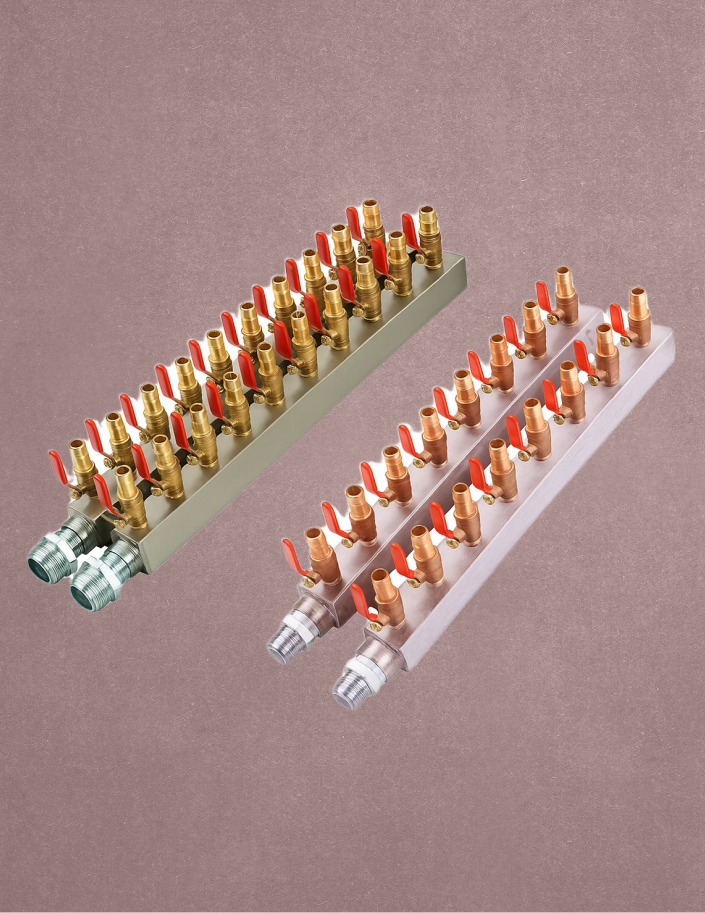

Ensures balanced water flow to multiple cooling channels in the mould. Built from high grade stainless steel for durability and pressure resistance.

Removes excess heat from the hydraulic circuit, maintaining oil viscosity and preventing system overheating.

©2025 . All Rights Reserved By Tokima Machinery Private Limited . Designed by Digju.com